NASA Break the Ice

NASA’s Break The Ice Lunar Challenge challenges teams to create a solution for mining lunar permafrost. The PSTDL’s Prototype Regolith In-situ Mining Rover with Onboard Surface Excavator (PRIMROSE) is a highly capable mining rover purpose-built to meet the demands of this challenge. PRIMROSE leverages proven terrestrial technology and the PSTDL’s experience with regolith excavation. Future work includes testing excavation of icy regolith in a cold chamber using the PRIMROSE excavator.Media

Members

Active

Dr. Paul van Susante

Dr. Paul van Susante Audrey Alexander

Audrey Alexander Robin Austerberry

Robin Austerberry Max Decker

Max Decker Connor Dinkelmann

Connor Dinkelmann Austen Goddu

Austen Goddu Marcello Guadagno

Marcello Guadagno Mason Krause

Mason Krause Austin McDonald

Austin McDonald Matthew Oujiri

Matthew Oujiri Jay Sweeney

Jay SweeneyAlumni

Parker Bradshaw

Parker Bradshaw Dana Brouse

Dana Brouse Leif Christsen

Leif Christsen Ben Engle

Ben Engle Lucas Frank

Lucas Frank Heather Goetz

Heather Goetz Ted Gronda

Ted Gronda William Jenness V

William Jenness V George Johnson

George Johnson Hunter McGillivray

Hunter McGillivray Collin Miller

Collin Miller Mack Miller

Mack Miller Joe Primeau

Joe Primeau Gregory Redlon

Gregory Redlon Suhayb Zeqlam

Suhayb ZeqlamProject Overview

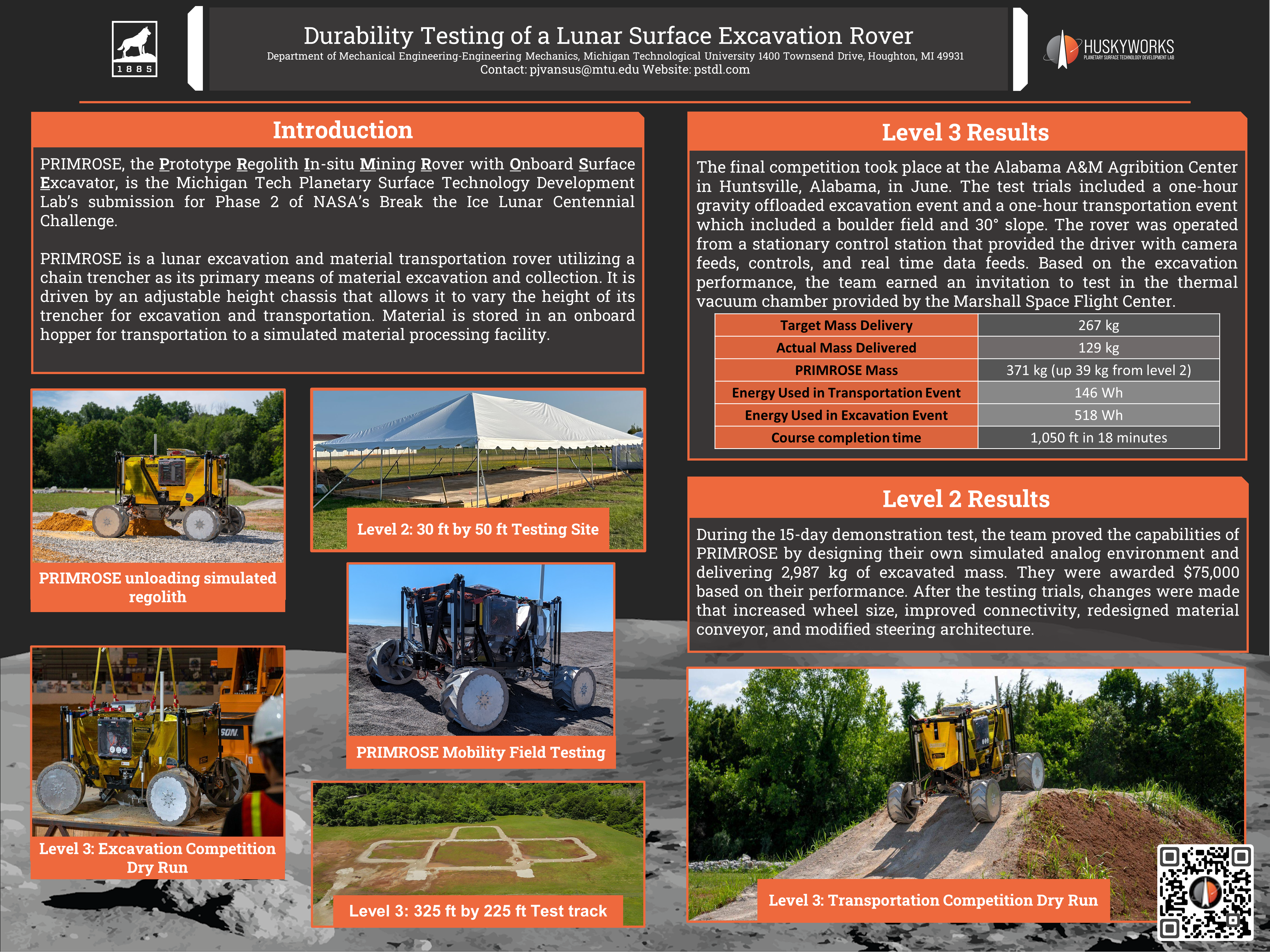

NASA’s centennial challenge program offers prizes to teams that demonstrate new technologies for NASA focus areas. For this challenge, teams must design and build a rover to excavate 800 kg of simulated lunar permafrost per day and deliver it to a simulated processing plant. The PSTDL designed and built the Prototype Regolith In-situ Mining Rover with Onboard Surface Excavator (PRIMROSE). PRIMROSE uses a chain trencher to excavate the hard permafrost and has advanced mobility capabilities. The vehicle has a 5kWh battery pack, and a dry weight of 332 kg

CONOPS

Transportation

The simulated processing plant and permafrost excavation area are 500m away from each other. This simulates the excavation area being inside the permanently shaded floor of a crater, and the processing plant on the rim of the crater where power is available. PRIMROSE travels over MTU-LHT-1A lunar regolith simulant in order to create a high fidelity lunar test environment. The wheels of the rover were designed in order to have high tractive performance on both loose granular regolith simulant and hard cemented lunar permafrost simulant. PRIMROSE is capable of independently steering, raising, and lowering each of its four wheels. The independent control of all wheels allows advanced mobility as the rover encounters rocks and craters.

Excavation

Chain trenchers are a proven method to excavate frozen ground on earth. PRIMROSE applies this technique to excavate and collect material from parallel trenches. These trenches leave behind a relatively flat and easy to traverse surface. The simple chain trencher is enabled by the independent actuation of each wheel. The excavator is rigidly attached to the frame, and the frame itself can be leveled on uneven terrain and lower the excavator down into the ground. Once the target mass of material has been collected, PRIMROSE traverses back to the simulated processing plant and drops off the batch of material.